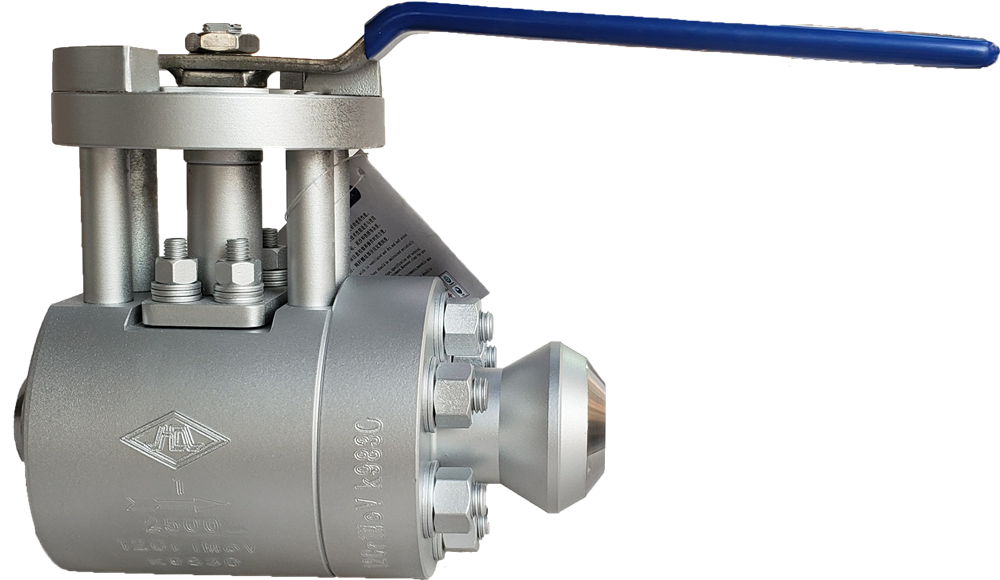

- Product features:

1. 1/4 turn greatly reduces the wear and friction of the packing and prevents leakage.

2. The anti-scouring ball structure ensures that the opening area is larger at the same opening at the beginning of the valve opening, and the pressure difference is reduced faster to reduce the scouring time of the high pressure difference, effectively extending the service life.

3. The graphite packing and valve seat warning are pre-tightened by butterfly springs to avoid locking under high temperature conditions.

4. Under some special working conditions (such as the main steam pipeline drain valve, which is responsible for the discharge of the startup heat pipe steam in addition to draining), due to the high flow rate and the impact force, the ball swings back and forth in the valve cavity at a high frequency to impact the valve stem, and the torque increases sharply, which is easy to cause the valve stem to break and twist, resulting in failure to use normally. The throttling orifice plate is used to disperse the energy when the valve is just opened to minimize the occurrence of scouring and cavitation.

5. The bolt cover connection is easy to disassemble and disassemble, and the accessories can be replaced and routinely maintained to increase the service life.

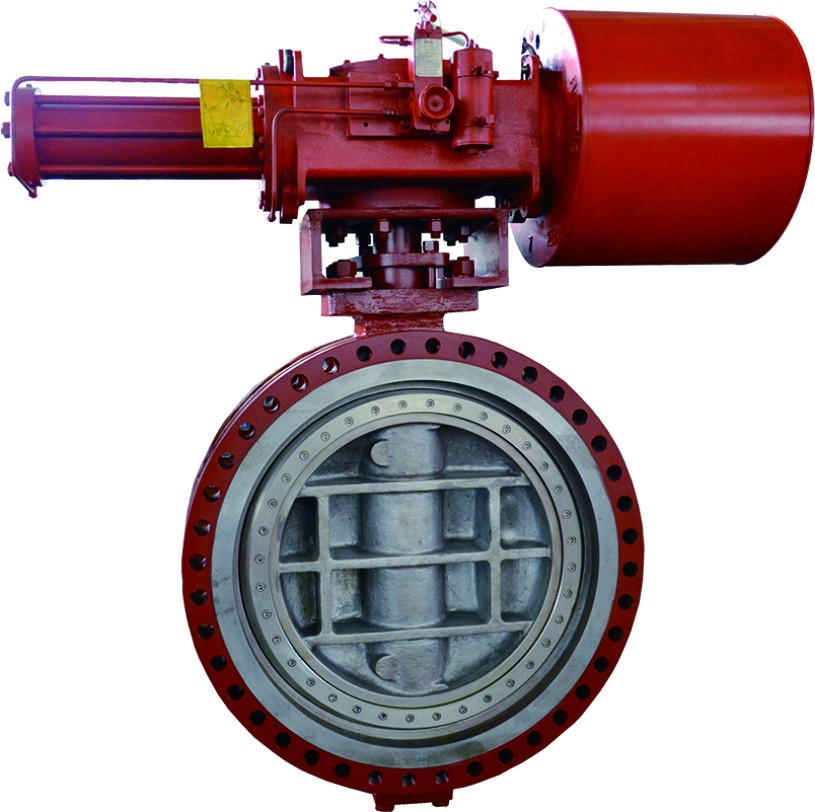

- Product use: flow and pressure control of steam turbine bypass and superheated steam bypass. Steam control and pipe heating of boiler soot blowing system. Steam pressure regulation of high temperature and high pressure steam pipeline.

- Product standard: GB/T 12224, ASME B16.34

- Nominal pressure: PN100-PN760 (600LB-4500LB)

- Nominal diameter: DN15-DN100 (1/2″-4″)

- Main material: A105, F316L, F22, F91, F92, 15CrMo, 12Cr1MoV

- Using temperature: 29℃~650℃

- Applicable media: water, steam

- Connection method: flange, welding

- Transmission method: handle, worm gear, pneumatic, electric